Making Patterned Metal Surfaces with Metal Lift-Off Techniques

Patterned thin films have had an enormous impact on modern technology, and though semiconducting elements typically grab the spotlight, metal surfaces have played a crucial role in various advanced applications such as materials characterization, biosensors, chemical sensors and microelectro-mechanical systems (MEMS).

As with silicon processing, there are various routes available for metal deposition. To achieve high fidelity, metal coating techniques are typically carried out under vacuum conditions to avoid the presence of contaminants. This ensures that metal coatings are laterally contiguous, with minimal defects. However, when making patterned metal surfaces, the goal is to selectively—rather than uniformly—coat a substrate.

Again, there are various routes to patterned metal surface coating, from soft lithography through to nanoimprinting. In this blog, we will explore the basics of metal pattern transfer via the metal lift-off technique.

What is Metal-Lift Off?

Metal lift-off is a way of creating microstructures on a surface using a sacrificial material. Photosensitive polymers (called photoresists) are commonly used in conventional pattern transfer by forming a negative of the pattern-to-be-etched from the surface using an electron-beam (e-beam), or UV light source. A similar method is used in metal lift-off, except the process is additive rather than subtractive.

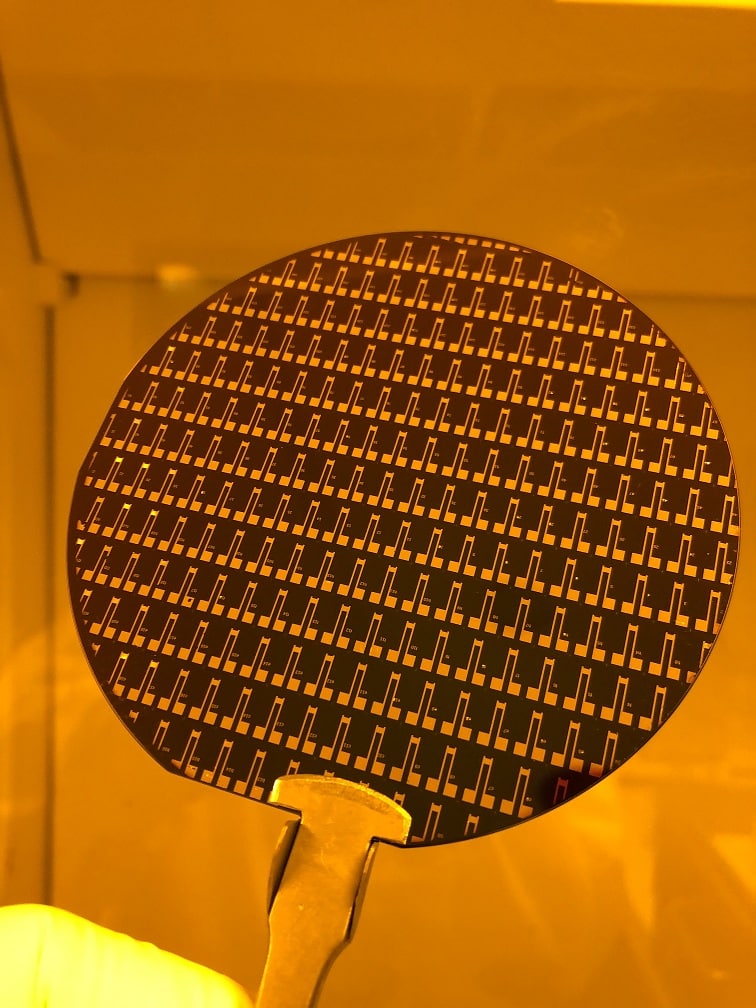

The basic principle of making patterned metal surfaces via lift-off techniques involves the selective application of a photoresist to a substrate. Metallization is then carried out using a technique like Physical Vapor Deposition (PVD), covering the substrate and the photoresist. Organic solvents are then used as a lift-off medium to remove the photoresist, along with any metal particles that have coated its surface, leaving an imprint of the resist mask in the newly coated surface.

Benefits of Metal-Lift Off Techniques

Lift-off methods are ideal for making patterned metal surfaces in shorter timeframes and at reduced cost to dry etching techniques. Additionally, dry etch methods can impact the structural properties of substrate layers—metal lift-off techniques do not. It is also a valuable alternative to wet chemical etching when making patterned metal surfaces using materials like gold, which often exhibits poor adhesion to resist materials under wet conditions.

Drawbacks of Metal Lift-Off Techniques

The main drawback of metal lift-off is the intricacy required to create stencils for successful lift-off. Depending on the deposition method, coating of the resist sidewalls may also lead to the generation of fence-like structures after the resist has been removed. This is a common side-effect in sputter coating.

Making Patterned Metal Surfaces with Platypus Technologies

At Platypus Technologies, we develop patterned metal surfaces on a made-to-order basis, deploying high-precision transfer techniques to ensure absolute accuracy, reliability, and repeatability. Our metal feedstocks include aluminium, copper, gold, platinum, and silver, while our substrates include ceramics, glass, flexible films, and silicon. If you would like more information about our metal coating solutions, why not contact a member of the Platypus Tech team today?