A Quick Guide to SU-8 Photolithography

SU-8 photolithography is a widely used microfabrication technique that uses a photosensitive negative epoxy called SU-8. The SU-8 is used to create micro and nanoscale patterns on a substrate’s surface, microstructures, and coatings for various applications. It is a popular choice because of its stable chemical, mechanical and thermal characteristics. SU-8 photolithography plays an important role in manufacturing microfluidics and microelectromechanical system components. This blog post will look at the procedure, applications, and instruments used for SU-8 photolithography.

Components Needed for SU-8 Photolithography

For SU-8 photolithography to be conducted accurately, there are a number of components that must be utilized. These components include a photoresist (SU-8), substrates, solvents, hotplates, a spinner, a mask aligner, and a UV light source.

SU-8

The SU-8 photoresist is a primary component in this process as it is the material required to create the required pattern. SU-8 is a negative epoxy-based photoresist with a high aspect ratio and thermal stability. When subjected to UV light, SU-8 undergoes a chemical reaction that helps leave behind a desired pattern on a substrate.

Substrates

A photoresist, such as SU-8, is dispensed onto a substrate. A substrate is a base material made of glass, polymers, or silicon. The substrate used in photolithography depends on the intended application and the desired properties of the final product.

Solvents

A solvent will be selected based on the type of photoresist used and is used to remove excess photoresist on a substrate surface. Once the unwanted photoresist is removed, the desired pattern will be exposed.

Mask Aligner

A mask aligner is used to align the photoresist with the required pattern. Once the two are aligned, the mask exposes selected sections of the photoresist, which enables a highly precise pattern to be created.

UV Light Source

Without a UV light source, the photolithography process would not be possible. As previously mentioned, the light source exposes the photoresist through the mask aligner and creates a chemical reaction. The chemical reaction is what creates the required pattern.

SU-8 Photolithography Procedure

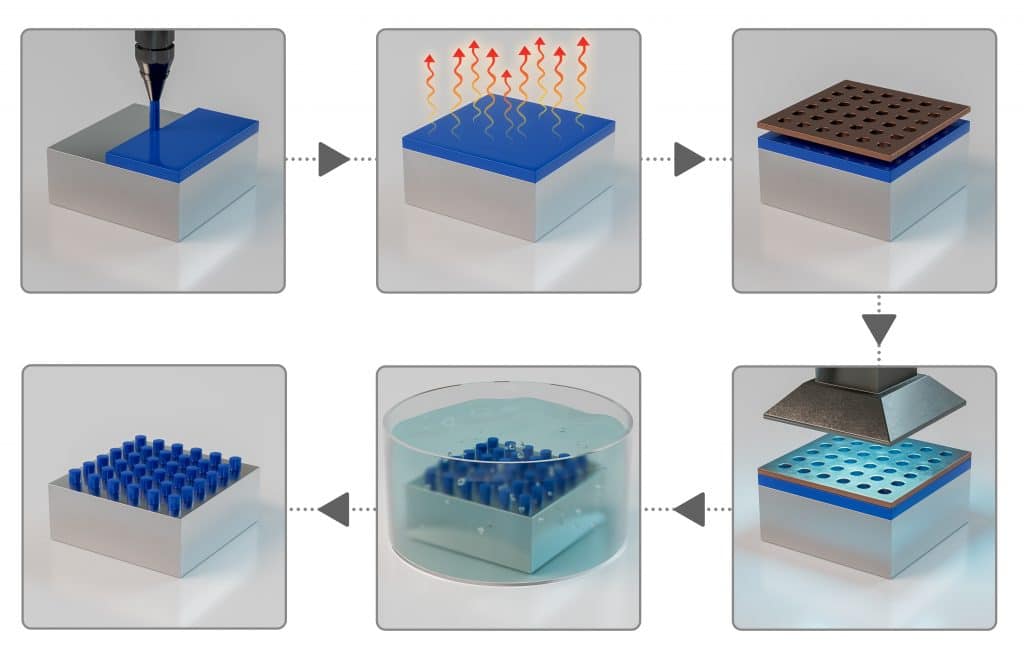

Several steps are involved in the SU-8 photolithography process, including substrate preparation, photoresist coating, UV light exposure, substrate development, and hard-baking the photoresist.

Before a substrate can be used in photolithography, it must be cleaned with a solvent such as acetone, methanol, or isopropyl alcohol. Once cleaned, the SU-8 is dispersed onto the substrate’s surface using a spinner (this process is called spin-coating), then the photoresist is soft-baked to allow for solvent evaporation. The following stages involve exposing the photoresist to UV light through a mask to create the required pattern, then removing unexposed areas with a solvent. The final stage of the process is to hard-bake the photoresist and permanently cure it.

To summarize, the photolithography procedure involves the following steps:

- Substrate cleaning

- Photoresist spin-coating

- Soft-baking

- UV exposure

- Removal of unexposed areas/pattern creation

- Hard-bake and curing

Learn more about the photolithography process here

Platypus Technologies and SU-8 Photolithography

Platypus Technologies provides a range of photolithography services for the fabrication of patterned surfaces. In this blog post, we have mentioned that photoresists are a key feature of photolithography processes. Platypus Technologies stocks negative and positive photoresists, including SU-8 patterned wafers for various applications such as developing biosensors, electrodes, MEMs devices, microfluidics, semiconductor devices, and many other applications.

Contact a member of Platypus Technologies today to learn more about SU-8 photolithography and how we can support your applications.