Masking & Micro-patterning

Micro-patterning is commonly done through masking. Creating a photomask involves important specifications that can directly affect a resulting pattern transfer. Mask material, environmental conditions, and type of resist should be considered. But prior to processing, photomask design characteristics must be determined.

Mask dimensions and thickness can be specified based the type of exposure. There are two main forms of exposure tools known as contact and projection printing. In contact photolithography, a desired mask pattern is fabricated to be the same size that should be replicated onto a substrate surface. In contact printing, the photomask scale is 1X, indicating no adjustments. While projection printing is often more complicated and involves altered features that may need to be made larger or smaller depending on the application. The photomask scale is usually adjusted to 4X or 5X reduction in projection printing.

Photomasks

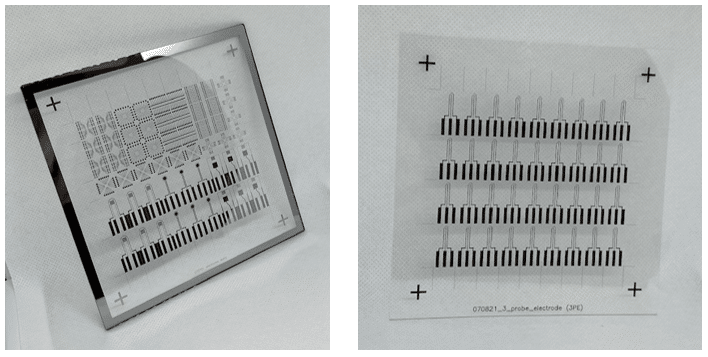

Photomasks can either be in the form of hard or soft masks. Hard masks are made of glass or quartz and soft masks consist of flexible polyester films. The rigidity of hard masks allows for increased solvent resistance, no temperature induced expansion, enhanced feature resolution, and convenient cleaning. The disadvantage of hard masks is that they are relatively more expensive compared to soft masks. Soft masks offer a low-cost solution for a faster fabrication process.

Most photomasks used in photolithography have two tones, dark and clear. Dark regions specify areas to be absorbed and clear tones are non-absorbing and reflect light. The absorber material can be selected based on user preference. Common absorber materials include chrome and aluminum due to high their reflectivity properties. The type of photoresist that is applied to a substrate will also determine which areas are exposed to UV light. With a positive resist, areas exposed to UV light dictate resist removal. Whereas with a negative resist, exposed areas are crosslinked. The optical density of an absorber material should also be considered since this value indicates the amount of light transmittance. In the UV spectrum this value should be around three.

Various environmental conditions can affect photomask longevity. Such conditions commonly include temperature, humidity, and tension. Mask aging can occur when processing conditions are varied. Therefore, all masking involved in photolithography processes should be conducted in a cleanroom environment. The temperature a mask is exposed to directly affects what is known as the thermal expansion coefficient. This value correlates to the degree to which a masking material changes in response to temperature changes. An ideal thermal expansion coefficient should be relatively low to prevent temperature induced distortions. Humidity is also determined by a humidity expansion coefficient. When humidity is increased, expansion can occur while decreased humidity causes shrinking. Hard masks are not affected by changes in humidity. Mechanical tension can occur due to contact exposure equipment and should be considered if using a soft photomask.

Platypus Technologies offers engineering design services equipped in photomask design using CAD software. In-house photolithography services can then be carried out to produce quality surfaces for a range of applications. Contact us today to assist with photomask design and implementation!