Emerging Technologies – Internet-of-Things

Internet of things (IoT) encompasses physical things that connect and exchange data with other technology. IoT offers increased connectivity, cloud computing, machine learning, and advancements to AI. Emerging advancements in IoT include machine monitoring, wearable health monitoring, inventory management, and public safety enhancements. IoT works through device-to-device communications that is conducted through sensor technology and actuators.

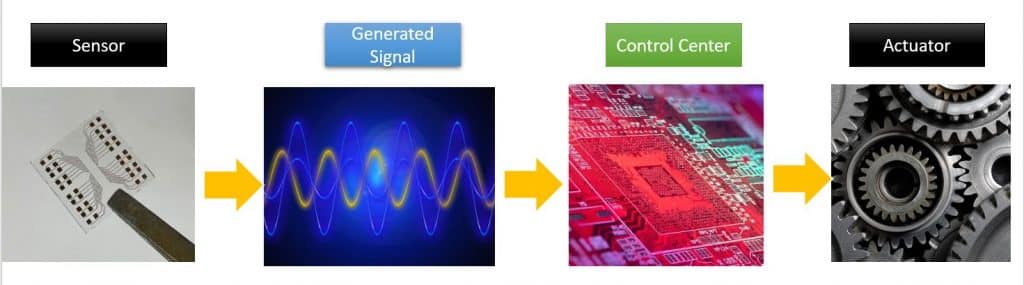

Sensors serve as the primary source of generating IoT data. Sensors work to convert energy into a different form by taking an outside occurrence and converting it into an electrical impulse. This impulse is then sent to a control center. An actuator is used in conjunction with sensors to convert electrical inputs into an observable physical action. In other words, an actuator converts a form of energy into a mechanical force. The general process flow of IoT technology is outlined below:

A custom patterned sensor is first used to detect certain outside parameters. The data generated from the sensor is then converted into a signal. This signal or impulse is then sent to a controller or control center. The control center works through pre-defined logic to cause a response to occur in an actuator. The decision determined by the controller is sent to the actuator in the form of an input. The actuator then interprets the input in order to perform a physical response.

Together, IoT based sensors and actuators are designed to engage cloud technologies. Cloud solutions are used to provide simplified data results. The accuracy of results mainly depends upon proper sensor calibration. Signals generated from sensors may drift over time due to environmental conditions like temperature and pressure. Sensor ranges may also shift over time causing inaccurate results. Sensor calibration should be prioritized to ensure proper sensor functioning.

With current trends heavily focused on progressing existing technological advancements, semiconductors serve as a key stakeholder. Environmental factors determine if a semiconductor acts as an insulator or conductor. The material properties of Silicon create the ideal surface for semiconductor fabrication. Silicon has very strong mechanical properties, easily conducts electricity, and is readily available. This can prevent mechanical wear and in part cause less of a need for sensor calibration in IoT based devices.

The current operations done at Platypus Technologies have directly impacted IoT device fabrication. Patterned substrate chips have been used by previous customers to enable proper functioning of IoT devices through integration of custom sensors. Examples include fabricating lead detection sensors and diagnostic based sensors. In addition, our exclusive BadgAIR device is made up of a chemical sensor chip that is made in-house, that is then inserted into an IoT device. Our manufacturing processes enable emerging technological advancements through extensive material science knowledge and surface fabrication services.

Our staff offers engineering consulting that is equipped to provide information on best practices for sensor fabrication. We offer in-house metal deposition and photolithography patterning services that can be used in semiconductor technologies equipped to aid IoT based devices. Contact us today to connect with one of our engineers at !