Why Coat Silicon Wafers with Metal Surfaces?

Silicon wafers are widely used in modern technology, serving mainly as the substrate for microelectronic circuits. In fact, it is extremely rare to find electronic devices that don’t contain some form of silicon-based substrate. The reason for this ubiquity is the unique semiconducting properties of silicon–but an electro-ceramic substrate is not the final word in integrated circuits. Metal surfaces also play a crucial role in semiconductor devices.

What is so Important about Metallization & Silicon Wafers?

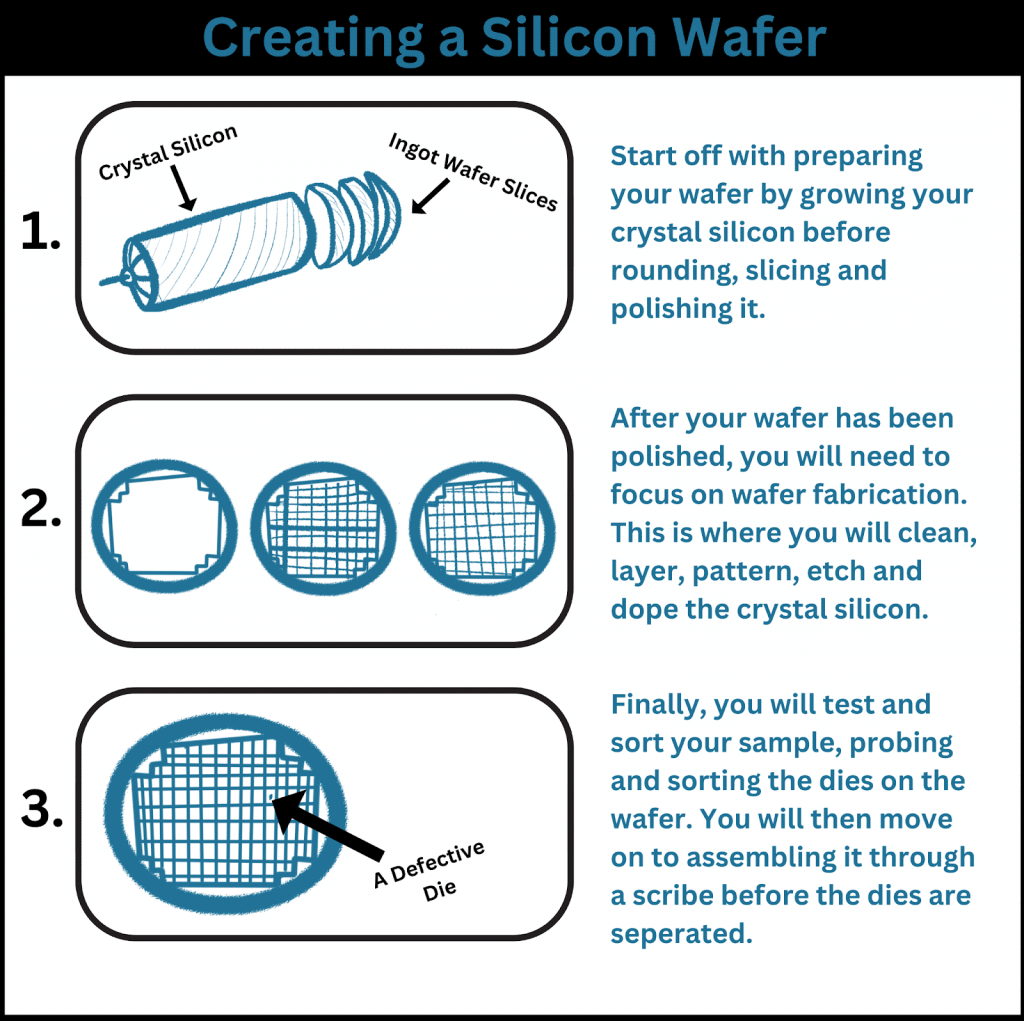

Metallization can be used to change the surface of a silicon wafer. This can be to improve its efficiency and utility or to help shape the wafer itself. Essentially, if you are looking to grow any type of semiconductor silicon wafer, you will need to start off with an ingot. These ingots are made inside a tube. Once they are grown, they can be sliced up into wafers, which are also known as substrates.

If you add certain properties to the ingot during its growth, you will find that you will be able to customize it to your needs. For instance, it will be able to conduct electricity with the right metal coating.

The process for creating a silicon wafer goes as follows:

Metal coating solutions are important to consider when you process your silicon wafer. Essentially, metallization is where you interconnect metal sheets so that the electric current can pass through the wafer. There are many different types of metals you can use for metallization, but the most common is aluminum. It comes with a variety of benefits, including:

· A low resistivity

· A good compatibility with silicon dioxide that can lower the likelihood of electromigration and junction spiking

There are a number of other materials that you can consider, as well as aluminum, for the metallization process. This includes gold, platinum and silver. You can create a metal surface through physical vapor deposition. The process of sputtering is used to push ions towards your wafer’s material. Deposition occurs when the atoms are discharged and hit the substrate. From there, they condense and a thin film appears on the wafer.

How can Metal Surfaces Enhance Silicon Wafers?

Metal coating solutions can change or improve the properties of the surface of your silicon wafers. Electrical conductivity is incredibly important when it comes to integrated circuits, due to the fact that there are a variety of different electronic components that are needed to keep the device fully functional. Examples of the use of integrated circuits include microprocessors and microcontrollers.

In addition, by providing a metal surface coating, you will find that the wafer’s mechanical strength can be increased. Its greater durability will make it less likely that it will be damaged when it is used. It is important to think about how your silicon wafer will react to thermal operations. If your electronic circuit heats up, and the wafer is not strong enough to handle it, the reliability of your electronic device will be compromised. A microchip needs to remain fully functional inside of an electronic product, so it is important that it remains mechanically strong.

Furthermore, using a metal coating on a silicon wafer is a great way to protect it from environmental factors, including oxidation and moisture. If you do not protect your wafer from these factors, you will find that the silicon wafer will end up degrading over time. Silicon wafers are used in a lot of electronics, but they can also be used in tire pressure sensor systems. So, they need to be optimized for any type of weather, meaning they need to be environmentally durable.

Are you Ready to Coat Your Silicon Wafer with a Metal Surface?

When you look into metal coating solutions, it is important that you consider your options to increase the efficiency of your silicon wafers. Platypus Technologies is ready to help you pick the best metal surface for you and your project. Why not get in contact to learn more? Call us on 608-237-1270 or email . We are ready to find the best metal surface for you.