Why Platinum Metal Surfaces are Ideal for High-Temperature Sensors

High-temperature measurement is a challenging prospect. Sensing elements must be robust enough to withstand the heat without degrading. Yet they also need the right conductivity to ensure measurement accuracy. Crucially: This conductivity must stay consistent across broad temperature ranges. Finding the right material for sensor surfaces is thus a balancing act.

Platinum is so often a standout material for high-temperature processes. It is routinely applied as a metal substrate in high-sensitivity sensing applications. But why? This article explores the benefits of platinum metal surfaces in more depth.

The High Melting Point Advantage

One of the most significant attributes of platinum is its high melting point. With a melting point of 1,768 degrees Celsius, platinum remains stable and retains its structural integrity in extreme temperatures. This property is crucial for sensors that operate in environments where other materials would simply melt or degrade. The high melting point ensures that platinum-based sensors maintain functionality and accuracy even under intense heat.

Chemical Stability: Resisting Corrosion and Oxidation

In addition to its impressive melting point, platinum’s chemical stability is a boon for sensor applications. Even at high temperatures, its resistance to corrosion and oxidation ensures longevity and consistent performance. This resistance is particularly beneficial in environments where sensors are exposed to corrosive agents like hydrochloric acids – which would rapidly degrade zinc nickel surfaces or nickel plating.

Conductivity and Precision in Measurement

The electrical conductivity of platinum is another factor that underscores its suitability for temperature sensors. As an excellent conductor of electricity, platinum ensures that electrical signals are transmitted with minimal loss, ensuring accurate measurements. This property is particularly vital in applications where precision is paramount, such as fuel cells or medical devices.

Biocompatibility: Bridging the Gap between Technology and Biology

For sensors used in medical applications, biocompatibility is a non-negotiable requirement. Platinum’s biocompatibility ensures it can be safely used in implantable sensors without causing adverse reactions with living tissues. This property sets platinum apart from many other metals, making it a preferred choice for biomedical applications.

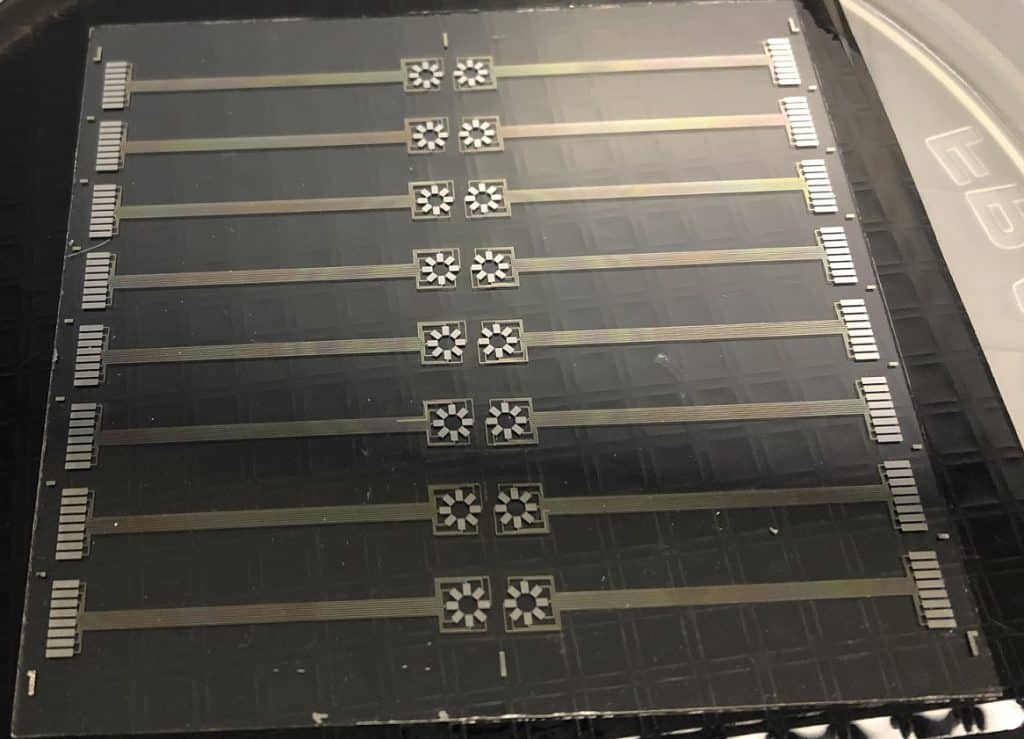

Surface Engineering: Enhancing Sensor Performance

The surface roughness of platinum can be engineered to optimize sensor performance. A rough texture on the surfaces of platinum promotes better adhesion of sensing materials, leading to improved sensor stability and performance. This engineered roughness ensures that the sensing materials remain firmly attached, reducing the chances of sensor failure.

Compatibility: Integrating with Other Materials

Platinum’s ability to integrate seamlessly with other materials, such as iridium oxide, further amplifies its appeal. This compatibility with other materials allows for the creation of hybrid sensors that leverage the strengths of multiple materials, ensuring enhanced performance and stability.

The Unparalleled Benefits of Platinum Metal Surfaces

The unique properties, such as a high melting point, chemical stability, electrical conductivity, biocompatibility, and surface engineering capabilities, make platinum metal surfaces the ideal choice for high-temperature sensors. Whether in an industrial furnace’s harsh environment or the human body’s delicate ecosystem, platinum proves its mettle time and again.

At Platypus Technologies, we recognize the unmatched potential of platinum and other platinum group metals. Our advanced metal coating solutions harness the power of this precious metal, ensuring that your sensors perform at their peak, regardless of the challenges they face. Explore our range of solutions and discover how we can elevate your sensor technology to new heights. Discover Platypus Technologies’ Metal Coating Solutions.