Nickel Thin Films: Properties and Applications

Nickel thin films are at the forefront of numerous technological advancements, offering unique properties that are indispensable in various industries. At Platypus Technologies, we specialize in the metal deposition through e-beam evaporation to create high-quality nickel coatings tailored for diverse industrial applications.

In this blog, we discuss the properties and applications of nickel coatings, as well as the advantages of producing nickel thin films via e-beam evaporation.

Properties and Applications of Nickel Thin Films

Physical and Chemical Properties

Nickel, a lustrous, silvery-white metal, has a high melting point (1,455 °C) and significant density (8.9 g/cm3).

Chemically, nickel has remarkable resistance to corrosion and oxidation, a trait that significantly extends the life and reliability of nickel-coated components. Nickel forms a thin nickel oxide passivation layer when exposed to air. This oxide layer protects the metal against attack by caustic agents including acids, bases and salts. These attributes make nickel an ideal candidate for enduring extreme environments.

Magnetic and Electrical Properties

One of nickel’s most notable features is its magnetic properties, coupled with excellent electrical conductivity. Nickel is a ferromagnetic material. Nickel’s magnetic properties make it ideal for use in magnetic storage technologies, such as hard drives and magnetic tapes.

The electrical resistivity of nickel is 6.4 μΩ-cm, which makes nickel a great conductor of electricity. These aspects are crucial in fields ranging from data storage to power generation to electrochemistry. In the realm of electronics, nickel thin films serve as electrical contacts and barriers for semiconductor devices.

Nickel films are also critical in catalysis processes and as electrodes in certain battery technologies.

Application of Nickel Thin Films in Satellite Technology

One of the critical applications of nickel is in the protective coatings of spacecraft components and satellite surfaces.

Space presents one of the most challenging environments, with extreme temperatures (both high and low), vacuum conditions, and intense radiation. Components used in space must withstand these harsh conditions without degrading.

Nickel’s excellent thermal stability and resistance to radiation damage make it an ideal choice for coatings in space applications. Nickel coatings can protect sensitive components from corrosion and wear, even in the harsh environment of space. Additionally, nickel’s magnetic properties are beneficial in components that require magnetic shielding.

Nickel Coatings via Vacuum Deposition

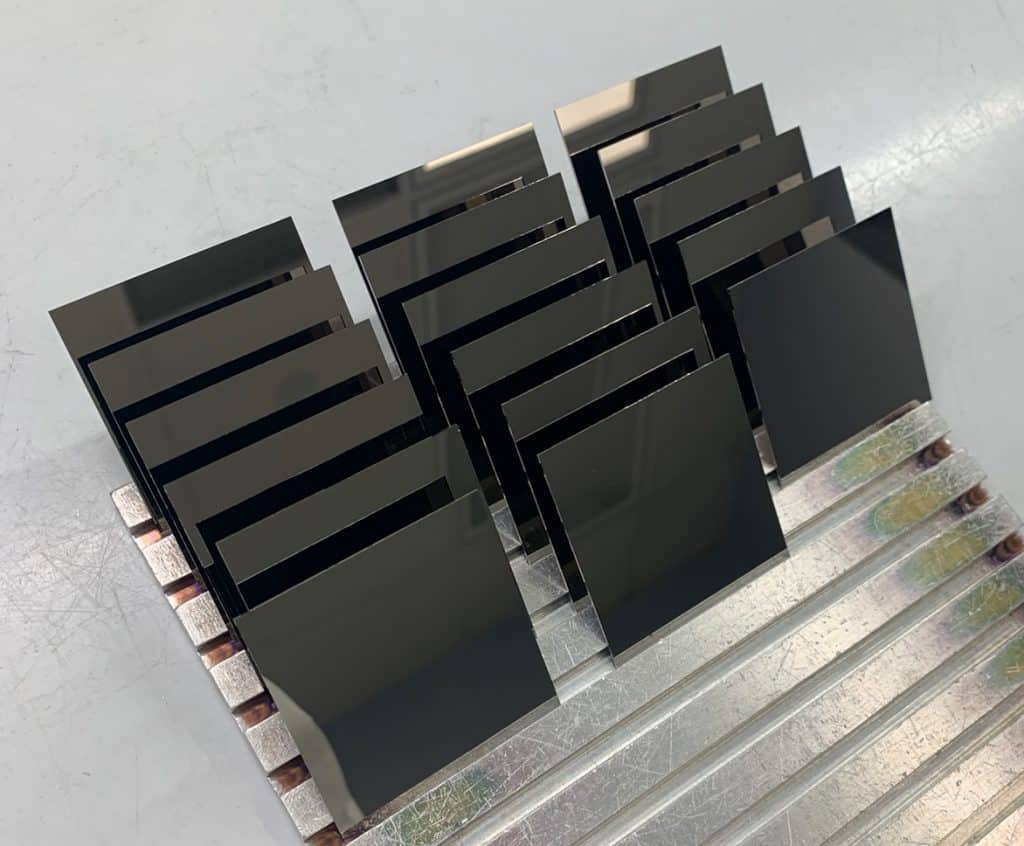

At Platypus Technologies, we specialize in metal deposition via e-beam evaporation, a vacuum process that enables high-purity coatings. This method offers unparalleled precision, purity, and control, particularly beneficial for the deposition of nickel coatings.

- High Purity and Quality: E-beam evaporation produces coatings of exceptionally high purity. This is because the process occurs in a vacuum, significantly reducing the risk of contamination compared to electroplating. For nickel deposition, this means the resulting films are extremely clean and high purity (99.995% pure nickel).

- Precise Thickness Control: The e-beam evaporation process allows for precise control over the thickness of the nickel film. At Platypus Technologies, we regularly produce films with thickness reproducibility within a few nanometers. This level of uniformity and consistency is harder to achieve in electroplating due to the complexities of chemical deposition dynamics.

- Better Adhesion: Nickel films deposited via e-beam evaporation have better adhesion to the substrate. At Platypus Technologies, we fabricate strong and adherent nickel thin films over a variety of substrates, including non-conductive materials such as glass, ceramic, silicon and Kapton.

In summary, e-beam evaporation offers superior control, purity, and versatility for nickel thin film deposition compared to electroplating. These advantages make it a preferred choice for high-tech industries where the quality and precision of the nickel coating are paramount.

Conclusion

Nickel thin films are a critical component in modern technology. At Platypus Technologies, we are proud to contribute to this field with our advanced metal deposition services, helping to push the boundaries of innovation.