Hydrogen Flame Annealing of Gold

As the demands of nanotechnology and material science continue to evolve, so too do the methodologies used to meet these needs. One key procedure that has revolutionized the field is the use of hydrogen flame annealing in the preparation of gold substrates. Gold, with its inherent chemical stability and ability to form strong bonds with certain biomolecules, has proven itself as a substrate of choice for numerous applications, including atomic force microscopy (AFM).

Gold Surfaces

A substrate’s performance is dictated largely by its chemical properties and interaction with the surrounding environment. Gold, being chemically inert against oxygen and stable against radicals, offers remarkable suitability for substrate preparation. Its additional ability to form stable gold-thiol bonds with proteins that include amino acids like methionine and cysteine make it uniquely versatile, notably in biosensing and bioelectronics applications.

Procedure for Hydrogen Flame Annealing

Hydrogen flame annealing is a process that enhances the purity and flatness of gold surfaces. In particular, hydrogen flame annealing is thought to remove the contaminants off gold surfaces, improve surface roughness, and increase grain size – critical requirements for high-resolution sample examination via AFM imaging.

The process makes use of a flammable hydrogen gas, a flow regulator, an anti-flashback arrester, a quartz plate, and a narrow-tip torch.

The hydrogen flame annealing process involves a series of carefully sequenced steps that begin with ensuring a clean workspace and properly preparing the gold thin film on a freshly cleaved mica substrate.

The flow of hydrogen is finely controlled, followed by lighting a torch and adjusting the resulting flame to about 2 inches in length.

The flame tip is brought close to the gold-coated mica, which sits atop a quartz plate, and moved back and forth slowly. The gold-coated mica is heating under the flame tip for approximately 30-60 seconds until the film glows with a dim orange color.

Finally, the flame is extinguished, and the gold-coated substrate is allowed to cool. This process results in contaminant-free, reconstructed Au (111) surfaces, which are extremely valuable for various scientific and industrial applications.

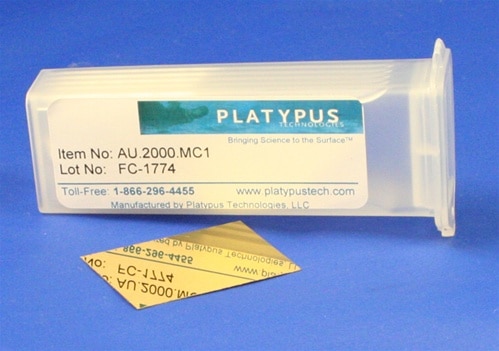

Gold-coated mica from Platypus Technologies

A prominent contributor to the advancements in substrate technology, Platypus Technologies offers gold-coated mica for use in a wide range of applications. This product leverages epitaxial growth of high-purity gold on mica under high vacuum conditions, lending itself excellently for the subsequent hydrogen flame annealing process. The 200-nm thick layer of gold, composed of flat Au (111) terraces, is ideally suited for high-resolution examinations and other applications. By leveraging extensive expertise and cutting-edge processes for production of gold films, Platypus Technologies ensures their gold-coated mica substrates meet the high standards demanded by contemporary material science and nanotechnology.

Conclusion

Hydrogen flame annealing offers an efficient and effective means of preparing gold substrates, providing a crucial tool of modern material science. Its contribution to the development of atomically flat gold surfaces cannot be overstated, driving advances in numerous fields, from biosensing to high-resolution sample examination. As we continue to push the boundaries of nanotechnology and material science, processes like hydrogen flame annealing will continue to play a central role in these advancements.

Keywords: Hydrogen flame annealing, Gold substrate preparation, Atomic force microscopy, Gold-thiol bonds, Chemisorption, Material science, Nanotechnology, Au (111) surfaces, Epitaxial growth.