Flexible Electronics

The field of flexible electronics continues to be on the rise as technological advances continue. New materials are beginning to be utilized in fabricating electrodes for flexible electronic applications.

Depositing conductive nanomaterials serve as a means of enhancing both electrical and structural properties of flexible materials. The success of developing flexible electronics primarily relies on electrode production which can present some challenges. Various types of flexible substrate materials used to make electrodes will be discussed as well as types of electrodes made in the flexible electronics industry.

Substrate Materials

Thermoplastic polymers represent a flexible substrate material. With this type of material, lower processing temperatures are often required. Whereas with inorganic substrate materials, such as silicon, high temperatures are used. Depositing conductive nanomaterials onto thermoplastic polymers and other flexible materials has been shown to have positive effects on flexible electronic manufacturing. Conducting polymers are used in place of natural and synthetic fibers and serve as the primary energy source in wearable technology. Creating conductive fibers can be done through conductive nanomaterials like carbon and graphene. Carbon nanotubes (CNTs) are produced through wet and dry spinning. Their mesh-like structure creates a high tensile strength, highly conductive, temperature resistant material.

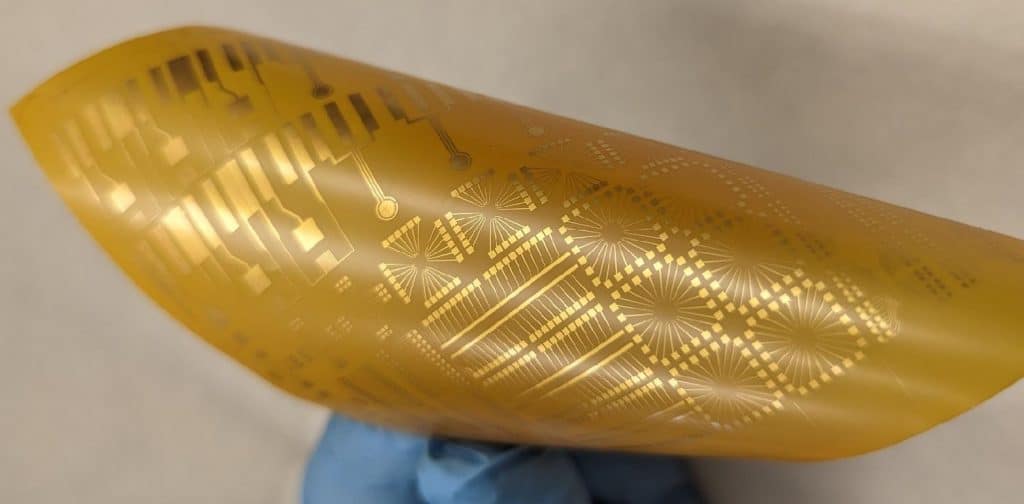

Newly emerging flexible substrate materials used for electrode fabrication include polyimide (PI), polyethylene terephthalate (PET), and polyethylene naphthalate (PEN). PI is a high temperature polymer that is particularly useful in applications requiring high thermal stability. It is also a very chemically resistant material. PET is also a valuable substrate material in flexible electronics. PET has a high melting point, moisture resistance, and ideal optical properties. This material has demonstrated much success with transfer printing, drop casting, and screen-printing electrode fabrication methods. PEN is a temperature resistant thermoplastic polymer that has a low coefficient of thermal expansion, minimal water absorption, and a very strong chemical resistance. However, tensile stress can cause degraded conductivity in some cases. Oxide coatings can help to enhance processing capabilities and prevent conductivity degradation in PEN and other flexible substrate materials.

Types of Electrodes

Electrodes involving flexible materials include interdigitated electrodes (IDEs), ion-selective and chemical-selective electrodes, and screen-printed electrodes. IDEs can be used as impedance sensors, pH sensors, and immunosensors. This type of electrode is used in biosensors that are either faradaic or non-faradaic. In faradaic biosensors, charge transfer occurs through electronic transfer, however in non-faradaic sensors, charge is stored. Previous research studies have fabricated IDEs using PEN and PET as an underlying flexible substrate material [1]. Fabricating ion-selective electrodes can be enhanced through carbon nanotubes. CNTs are commonly used to create a transducing layer onto ion-selective electrodes to help promote electron transfer. In addition to electrochemical impedance spectroscopy (EIS) and cyclic voltammetry (CV), ion-selective electrodes can be optimized. Screen-printed electrodes (SPEs) are used to produce electrochemical based sensors. Screen-printing involves depositing an ink onto a substrate material via a screen. This method of fabrication supports the employment of flexible substrate materials such as PET, which can allow for enhanced electrochemical properties.

Platypus Technologies is currently offering electrode designs that could be used in flexible electronic applications. Our engineers are also working to create new electrodes on flexible substrates. Contact us today to inquire about our newly developing electrodes!