Copper Thin Films for Corrosion Testing

Platypus Technologies currently offers coatings of gold, silver, and platinum and now we are launching a new product: Copper coatings.

Copper is a metal with high electrical and thermal conductivity, and for this reason thin films of copper are widely used in integrated circuits and printed circuit boards. Copper films also find application as anti-biofouling or anti-microbial coatings. However, the performance of these copper films can be compromised in the presence of corrosive compounds. For example, it is well known that sulfur, ammonia, and oxidizing acids corrode copper. When scientist and engineers design new materials, compounds, or chemicals that will be in contact with electronic devices, they test for the corrosive effects of these chemicals on copper films. If the material attacks the copper film, it will cause damage to the electronic devices containing copper.

Corrosion Studies – Copper Mirror Method

Corrosion is an oxidation-reduction reaction where a metal loses electrons. In the case of copper, it tends to lose two electrons and form a green-colored compound called patina. In extreme cases, the thin film of copper is entirely removed from the surface when a strong oxidizing compound is applied. These effects are used to assess the damage that certain materials will do to copper.

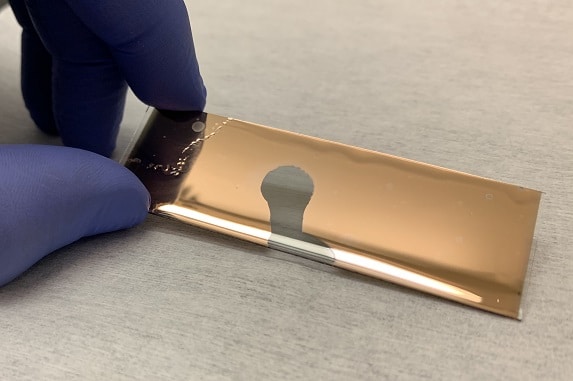

For example, flux used for soldering microelectronic components can cause corrosion of copper, and the standard “copper mirror” method is used to assess the severity of copper corrosion. In this method, a droplet of the solder flux is deposited directly on the surface of a polished glass plate coated with a thin film of copper, which has a shiny, mirror-like surface. After 24 hours, the droplet is removed from the copper film by rinsing with isopropanol, and the copper film is carefully examined. If any possible copper removal or color change is found, it is an indication that the flux corrodes the copper. Additional corrosion testing details are specified by ASTM Standards (D 2671 – 00), including testing at elevated temperatures, and under extreme humidity and dust environments.

Copper-coated glass slides from Platypus Technologies can be used to perform corrosion tests defined by ASTM or IPC standards. The 50 nm copper film is deposited onto the polished glass under high vacuum, inside a cleanroom, and stored in an inert environment to conserve the quality of the surface.

Contact a member of the Platypus Technologies team to discuss partnership opportunities with us. We would be happy to supply copper-coated substrates tailored to your specifications.