Biosensors Explained – An Overview of Modern Bioelectronic Manufacturing

Biosensors are the core component of many cutting-edge technological initiatives – from state-of-the-art healthcare devices to the agricultural and industrial manufacturing sectors.

The diverse and seemingly ubiquitous adoption of biosensor technology has been driven by innovations in both micro-manufacturing processes and the field of photolithography services. Behind those innovations is an increasing demand for more sophisticated sensing devices used throughout a broad range of commercial, industrial and consumer industries.

Advancements in the Biosensor Fabrication Process

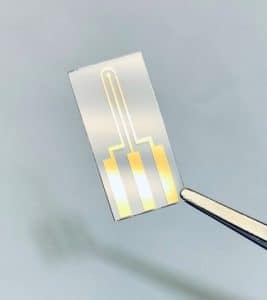

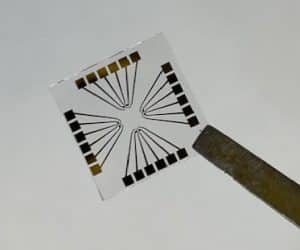

Chip and sensor OEMs are now capable of delivering precision micro-structured platforms that are manufactured with extreme accuracy and consistency. These advancements offer the high level of repeatability that is required for critical medical and commercial applications.

The reliability of the modern micro-manufacturing industry provides leading biosensor fabricators such as Platypus Technologies with all of the tools and materials needed to rapidly develop custom prototypes and proofs of concept which are truly optimized for your unique bioelectronics application.

What Exactly Is a Biosensor and How Does It Work?

At the most basic level, biosensors are simple analytical devices that detect the presence of specific chemical substances. A biosensor performs this basic function by using a sensitive biological component (e.g. cell tissue, microorganisms, nucleic acids, etc.) in conjunction with a physicochemical detector. The detector, or transducer, then generates a signal when the targeted bioelectric reaction takes place.

Biosensor chips are more sophisticated elements constructed from numerous custom biosensors. Each unique biosensor can be monitored separately or employed in complex process analysis. Biosensor chips are therefore functionally classified according to the type of transducer or bioreceptor utilized.

There are three distinct generations of biosensors that are currently on the market as of 2022:

First Generation Biosensors

With first generation biosensors, the reaction of the electrons disperses to the sensor and triggers the electrical reaction from the transducer.

Second Generation Biosensors

In second generation chips, the sensors use specialized mediators that transfer electrons between the sensor and transducer to generate a more optimal signal response.

Third Generation Biosensors

Third generation chips do not use a mediator. Signals from the sensing agent are transferred directly to the transducer through direct electron transfer (DET) technology.

Modern Technological Uses and Applications of Biosensors

From wearable gadgets such as smartwatches, to cutting-edge medical devices, to agricultural and industrial pollution monitors – biosensors see a myriad of uses throughout the modern consumer, commercial and industrial sectors. Below are just a few of the diverse use-cases for biosensor technology.

- Healthcare monitoring devices in both consumer and professional applications.

- Heart rate monitors in smartwatches, fitness trackers, and other wearable tech devices.

- Professional medical monitoring devices.

- Genetic screening and gene mapping applications.

- Screening and early detection for disease.

- Patient health monitoring and management.

- Crop and soil monitoring in agricultural applications.

- Used to track crop disease, detect pesticides / herbicides, etc.

- Industrial material monitoring, handling and processing.

- Pollution monitoring and control in a wide range of sustainability initiatives.

Custom Biosensor Technology Designed and Fabricated for Your Application

Platypus Technologies strives to remain at the forefront of the ever-evolving biosensor chip industry. Contact us today to learn more about our design and fabrication expertise, or to discuss your unique needs for quality-engineered biosensor products.